Quality Assurance (Bale tie Wire / Quick Link)

BEST QUALITY ALWAYS MADE IN BEST MACHINES.

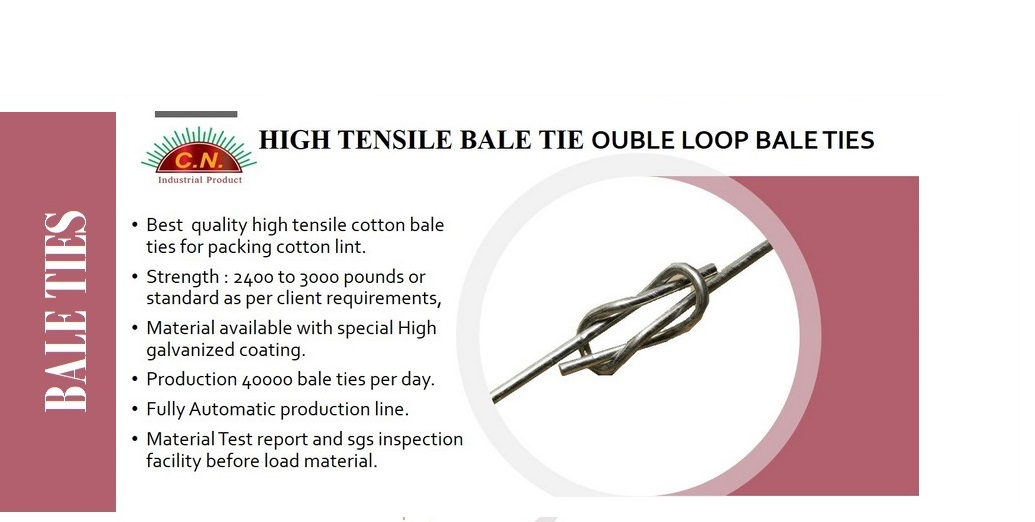

C.N.I.P remains committed to designing and developing innovative products to meet the cotton ginning bales wire requirements of both current and emerging markets. To maintain our role as a leader in the design and manufacture of cotton ginning bale packing material (cotton bale ties / quick link) we will continue to invest in the best equipment and people. That combination is one our competition cannot match.

Research & Development

A strong research and development program is fundamental to innovation. At C.N.I.P, our innovative muscle derives from a highly trained and experienced research staff backed by a fully equipped laboratory for conducting rigorous performance and endurance testing. Typically, development projects range from endurance testing of new seal materials to performance testing of custom housing geometries. Prototypes are frequently subjected to elevated ambient conditions to simulate actual operating environments and gain more reliable data. Laboratory facilities include dynamometers ranging from 3 to 250 horsepower, two test cells for measuring radial,High Tensile Measuring Testing Machine, Galvanised Testing Machine.

Engineering

C.N.I.P brings more than a 25 Years of experience in the design and manufacture of Cotton Gin Machinery & Related Products to each new project. Through experience, we can quickly identify and focus on the critical aspects of every design project and develop an approach to satisfy the most demanding performance requirements. Our engineers use state-of-the-art solid modeling software, design for manufacturing techniques and fast prototype capability to move rapidly from initial concept to first production. Our application design expertise encompasses a broad range of markets, among them: Bale ties, Cotton Bale Wire, Quick Link, Bale Packing Wire, Single loop bale wire, double loop bale wire, bale ties for packing cotton bale.

Manufacturing

Advanced technology is central to our manufacturing operations. Using state-of-the-art equipment and methods translates into speed, uniformity and consistent high quality. Computer numerical control (CNC) machining centers on the factory floor are linked to a central server for rapid loading of machine programs. This direct interface speeds set-up which, in turn, boosts productivity. Automated machining also improves precision in Drawing, Cutting, Galvanizing, looping and other critical operations. Greater accuracy and repeatability means consistent high quality — your next c.n will perform as well as your last.

Quality Control

At C.N.I.P, quality is designed into every component and every gin bale wire we build. From concept, through development and on into production, our focus is to provide durable and reliable products that satisfy every customer requirement. Quality is monitored throughout the production process using state-of-the-art gauging systems. Critical points on every production unit receive 100% inspection. All gauges and inspection instruments are calibrated to meet and we conform to inspection system standards when necessary. For nearly two decades, our coordinate measuring machine (CMM) has had an integral role in our quality program. This highly accurate and versatile tool helps us establish and monitor production quality standards

Customer Support Worldwide

C.N.I.P operates in a global marketplace. We are keenly aware of the need to provide prompt delivery of our products to customers worldwide and have in place an international network of distributors to meet this need. Our computerized inventory control system tracks the more than 10,000 parts we stock in our 20,000 square foot parts warehouse. We also maintain E-mail capability and a site on the worldwide web to speed communication between us, our distributor network and our customers.

C.N.I.P remains committed to designing and developing innovative products to meet the cotton ginning bales wire requirements of both current and emerging markets. To maintain our role as a leader in the design and manufacture of cotton ginning bale packing material (cotton bale ties / quick link) we will continue to invest in the best equipment and people. That combination is one our competition cannot match.

Research & Development

A strong research and development program is fundamental to innovation. At C.N.I.P, our innovative muscle derives from a highly trained and experienced research staff backed by a fully equipped laboratory for conducting rigorous performance and endurance testing. Typically, development projects range from endurance testing of new seal materials to performance testing of custom housing geometries. Prototypes are frequently subjected to elevated ambient conditions to simulate actual operating environments and gain more reliable data. Laboratory facilities include dynamometers ranging from 3 to 250 horsepower, two test cells for measuring radial,High Tensile Measuring Testing Machine, Galvanised Testing Machine.

Engineering

C.N.I.P brings more than a 25 Years of experience in the design and manufacture of Cotton Gin Machinery & Related Products to each new project. Through experience, we can quickly identify and focus on the critical aspects of every design project and develop an approach to satisfy the most demanding performance requirements. Our engineers use state-of-the-art solid modeling software, design for manufacturing techniques and fast prototype capability to move rapidly from initial concept to first production. Our application design expertise encompasses a broad range of markets, among them: Bale ties, Cotton Bale Wire, Quick Link, Bale Packing Wire, Single loop bale wire, double loop bale wire, bale ties for packing cotton bale.

Manufacturing

Advanced technology is central to our manufacturing operations. Using state-of-the-art equipment and methods translates into speed, uniformity and consistent high quality. Computer numerical control (CNC) machining centers on the factory floor are linked to a central server for rapid loading of machine programs. This direct interface speeds set-up which, in turn, boosts productivity. Automated machining also improves precision in Drawing, Cutting, Galvanizing, looping and other critical operations. Greater accuracy and repeatability means consistent high quality — your next c.n will perform as well as your last.

Quality Control

At C.N.I.P, quality is designed into every component and every gin bale wire we build. From concept, through development and on into production, our focus is to provide durable and reliable products that satisfy every customer requirement. Quality is monitored throughout the production process using state-of-the-art gauging systems. Critical points on every production unit receive 100% inspection. All gauges and inspection instruments are calibrated to meet and we conform to inspection system standards when necessary. For nearly two decades, our coordinate measuring machine (CMM) has had an integral role in our quality program. This highly accurate and versatile tool helps us establish and monitor production quality standards

Customer Support Worldwide

C.N.I.P operates in a global marketplace. We are keenly aware of the need to provide prompt delivery of our products to customers worldwide and have in place an international network of distributors to meet this need. Our computerized inventory control system tracks the more than 10,000 parts we stock in our 20,000 square foot parts warehouse. We also maintain E-mail capability and a site on the worldwide web to speed communication between us, our distributor network and our customers.

A strong research and development program is fundamental to innovation. At C.N.I.P, our innovative muscle derives from a highly trained and experienced research staff backed by a fully equipped laboratory for conducting rigorous performance and endurance testing. Typically, development projects range from endurance testing of new seal materials to performance testing of custom housing geometries. Prototypes are frequently subjected to elevated ambient conditions to simulate actual operating environments and gain more reliable data. Laboratory facilities include dynamometers ranging from 3 to 250 horsepower, two test cells for measuring radial,High Tensile Measuring Testing Machine, Galvanised Testing Machine.

Engineering

C.N.I.P brings more than a 25 Years of experience in the design and manufacture of Cotton Gin Machinery & Related Products to each new project. Through experience, we can quickly identify and focus on the critical aspects of every design project and develop an approach to satisfy the most demanding performance requirements. Our engineers use state-of-the-art solid modeling software, design for manufacturing techniques and fast prototype capability to move rapidly from initial concept to first production. Our application design expertise encompasses a broad range of markets, among them: Bale ties, Cotton Bale Wire, Quick Link, Bale Packing Wire, Single loop bale wire, double loop bale wire, bale ties for packing cotton bale.

Manufacturing

Advanced technology is central to our manufacturing operations. Using state-of-the-art equipment and methods translates into speed, uniformity and consistent high quality. Computer numerical control (CNC) machining centers on the factory floor are linked to a central server for rapid loading of machine programs. This direct interface speeds set-up which, in turn, boosts productivity. Automated machining also improves precision in Drawing, Cutting, Galvanizing, looping and other critical operations. Greater accuracy and repeatability means consistent high quality — your next c.n will perform as well as your last.

Quality Control

At C.N.I.P, quality is designed into every component and every gin bale wire we build. From concept, through development and on into production, our focus is to provide durable and reliable products that satisfy every customer requirement. Quality is monitored throughout the production process using state-of-the-art gauging systems. Critical points on every production unit receive 100% inspection. All gauges and inspection instruments are calibrated to meet and we conform to inspection system standards when necessary. For nearly two decades, our coordinate measuring machine (CMM) has had an integral role in our quality program. This highly accurate and versatile tool helps us establish and monitor production quality standards

Customer Support Worldwide

C.N.I.P operates in a global marketplace. We are keenly aware of the need to provide prompt delivery of our products to customers worldwide and have in place an international network of distributors to meet this need. Our computerized inventory control system tracks the more than 10,000 parts we stock in our 20,000 square foot parts warehouse. We also maintain E-mail capability and a site on the worldwide web to speed communication between us, our distributor network and our customers.

C.N.I.P brings more than a 25 Years of experience in the design and manufacture of Cotton Gin Machinery & Related Products to each new project. Through experience, we can quickly identify and focus on the critical aspects of every design project and develop an approach to satisfy the most demanding performance requirements. Our engineers use state-of-the-art solid modeling software, design for manufacturing techniques and fast prototype capability to move rapidly from initial concept to first production. Our application design expertise encompasses a broad range of markets, among them: Bale ties, Cotton Bale Wire, Quick Link, Bale Packing Wire, Single loop bale wire, double loop bale wire, bale ties for packing cotton bale.

Manufacturing

Advanced technology is central to our manufacturing operations. Using state-of-the-art equipment and methods translates into speed, uniformity and consistent high quality. Computer numerical control (CNC) machining centers on the factory floor are linked to a central server for rapid loading of machine programs. This direct interface speeds set-up which, in turn, boosts productivity. Automated machining also improves precision in Drawing, Cutting, Galvanizing, looping and other critical operations. Greater accuracy and repeatability means consistent high quality — your next c.n will perform as well as your last.

Quality Control

At C.N.I.P, quality is designed into every component and every gin bale wire we build. From concept, through development and on into production, our focus is to provide durable and reliable products that satisfy every customer requirement. Quality is monitored throughout the production process using state-of-the-art gauging systems. Critical points on every production unit receive 100% inspection. All gauges and inspection instruments are calibrated to meet and we conform to inspection system standards when necessary. For nearly two decades, our coordinate measuring machine (CMM) has had an integral role in our quality program. This highly accurate and versatile tool helps us establish and monitor production quality standards

Customer Support Worldwide

C.N.I.P operates in a global marketplace. We are keenly aware of the need to provide prompt delivery of our products to customers worldwide and have in place an international network of distributors to meet this need. Our computerized inventory control system tracks the more than 10,000 parts we stock in our 20,000 square foot parts warehouse. We also maintain E-mail capability and a site on the worldwide web to speed communication between us, our distributor network and our customers.

Advanced technology is central to our manufacturing operations. Using state-of-the-art equipment and methods translates into speed, uniformity and consistent high quality. Computer numerical control (CNC) machining centers on the factory floor are linked to a central server for rapid loading of machine programs. This direct interface speeds set-up which, in turn, boosts productivity. Automated machining also improves precision in Drawing, Cutting, Galvanizing, looping and other critical operations. Greater accuracy and repeatability means consistent high quality — your next c.n will perform as well as your last.

Quality Control

At C.N.I.P, quality is designed into every component and every gin bale wire we build. From concept, through development and on into production, our focus is to provide durable and reliable products that satisfy every customer requirement. Quality is monitored throughout the production process using state-of-the-art gauging systems. Critical points on every production unit receive 100% inspection. All gauges and inspection instruments are calibrated to meet and we conform to inspection system standards when necessary. For nearly two decades, our coordinate measuring machine (CMM) has had an integral role in our quality program. This highly accurate and versatile tool helps us establish and monitor production quality standards

Customer Support Worldwide

C.N.I.P operates in a global marketplace. We are keenly aware of the need to provide prompt delivery of our products to customers worldwide and have in place an international network of distributors to meet this need. Our computerized inventory control system tracks the more than 10,000 parts we stock in our 20,000 square foot parts warehouse. We also maintain E-mail capability and a site on the worldwide web to speed communication between us, our distributor network and our customers.

At C.N.I.P, quality is designed into every component and every gin bale wire we build. From concept, through development and on into production, our focus is to provide durable and reliable products that satisfy every customer requirement. Quality is monitored throughout the production process using state-of-the-art gauging systems. Critical points on every production unit receive 100% inspection. All gauges and inspection instruments are calibrated to meet and we conform to inspection system standards when necessary. For nearly two decades, our coordinate measuring machine (CMM) has had an integral role in our quality program. This highly accurate and versatile tool helps us establish and monitor production quality standards

Customer Support Worldwide

C.N.I.P operates in a global marketplace. We are keenly aware of the need to provide prompt delivery of our products to customers worldwide and have in place an international network of distributors to meet this need. Our computerized inventory control system tracks the more than 10,000 parts we stock in our 20,000 square foot parts warehouse. We also maintain E-mail capability and a site on the worldwide web to speed communication between us, our distributor network and our customers.

C.N.I.P operates in a global marketplace. We are keenly aware of the need to provide prompt delivery of our products to customers worldwide and have in place an international network of distributors to meet this need. Our computerized inventory control system tracks the more than 10,000 parts we stock in our 20,000 square foot parts warehouse. We also maintain E-mail capability and a site on the worldwide web to speed communication between us, our distributor network and our customers.