ABOUT PRAMUKH

Pramukh Makes the Difference

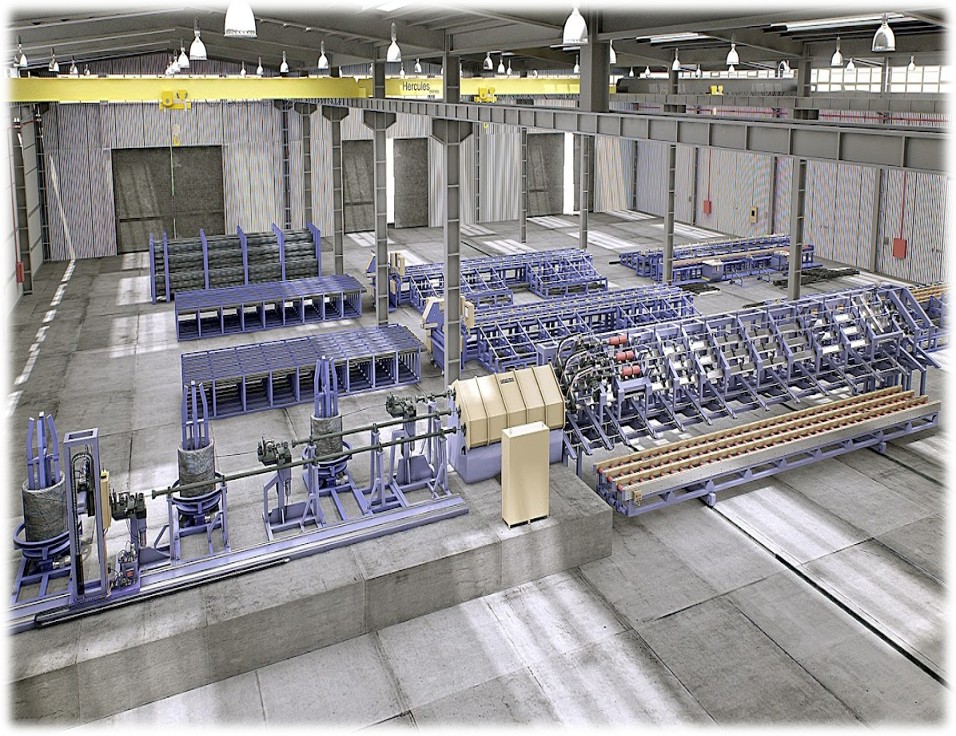

Pramukh Steel Industries (PSI) is a world-leading manufacturer, exporter, and supplier of high-tensile wires used for packaging cotton bales, scrap tires, and various other baled materials. PSI manufactures tie wires, double loop wires, and high-tensile galvanized wires using only the best-grade raw materials. The company develops and manufactures its bale packing wires using best-quality German machinery. Pramukh’s cutting-edge wire bending and cutting technology contributes to sustainability in the packaging value chain by minimizing resource usage. Pramukh Steel Industries has been in business for more than 25 years, operates three production locations in one country, and employs a global workforce of around 250 people, about 16% of whom are based in the African continent.

The company also manufactures different types of packaging wires used for cotton bale packing, scrap tire packing, fiber bale packing, metal scrap packing, and heavy engineering product packing. PSI is the only manufacturer in India that provides high-tensile bale packing wire and double loop wire. PSI is also the sole supplier in 29 countries, covering all types of bale packing wire requirements. PSI is a market leader in the field of precision high-carbon wire manufacturing, Bale Tie wire Manufacturing, Double Loop Bale tie Wire Manufacturing. with three manufacturing locations in Ahmedabad, Gujarat, India. The company employs a global workforce, with offices located in India, as well as the USA, Mexico, Uganda, Tanzania, Kenya, and Cameroon. PSI is listed with FIEO (Federation of Indian Export Organisations) and is an ISO-certified company.

- India’s Largest Supplier of Finished Bale Ties.

- Leading Producer of Double Loop Bale Tie Wire

- India's Leading Manufacturer of High-Tensile Galvanized Wire

- Primary Merchant Exporter of High Carbon Steel Wire in India

- A Global Leader in Premium Packing Wire Solutions from India

- A Dominant Market Leader in the Export of Finished Bale Ties

- World Biggest High carbon Steel Wires Exporter in india.

- Different types of packing wire / ties manufacturer.

- High quality tyre packing bale ties.

- Manufacturing of different other wires as per drawings.

- High quality silgne loop wire manufacturer.

- Supplier largest different types of double loop, single loop wires.

- Unbreackeble Tyre bale Packing Wire manufacturer.

- Indias biggest manufacturer & exporter of bale packing wires.

Product

As a leading manufacturer and exporter of bale tie wires, double loop bale tie wires, and high tensile bale wires, Pramukh steel industries offers a unique spectrum of products along with after-sales service and custom solutions for the packing industry. These offerings are tailored to satisfy every customer preference, enabling packing industries to achieve extremely high efficiency rates and maintain a competitive advantage throughout the entire lifecycle of their unit. Furthermore, Pramukh steel industries is a leader in the field of precision wires and high strength/tensile wire products.

ExploreBenifit

Higher strength, better corrosion resistance and improved formability and ductility at affordable cost.

Quality approved from certifying agencies across the world – USA, Africa, Europe, Japan, Australia etc.

Backed by a dedicated Product Application Group Engineers and Technology Group Researchers to continually to develop the next generation of products.

Complete in-house control from iron ore to wire, state-of-the-art fully automated fumeless centralised pickling facility.

Product Range

Pramukh Steel Industries has a long tradition of leadership in baling wire innovation. Today, the company comprises many segments, focusing primarily on Packing Solutions.

Pramukh Steel Industries Wire Solutions offers high-quality, higher-strength, and high-carbon wire that is technologically advanced and provides customer-specific solutions for various packing industries. Sourcing original materials from Pramukh contributes significantly to keeping production costs down and quality standards up. For all high-strength wires, this ensures optimal machine reliability, consistent quality and performance, and accurate interaction with other components.

As a leading manufacturer of high-tensile wires for bale packing, tyre packing, and scrap packing, Pramukh offers a unique spectrum of products and services, providing the best packing wires tailored to satisfy every customer preference. Pramukh enables wire end-users to achieve extremely high efficiency rates and a competitive advantage throughout the entire life cycle of their unit. Furthermore, Pramukh is a leader in the field of precision high-strength wires.

After Sales Service

PSI commits to their clients for all HIGHE TENSILE WIRES are sale with warranty or guaranty. PSI accompanies customer’s equipment’s throughout their lifecycle by providing higher strength wires and solutions of packing industries. Through premium and innovative in baling wire products, PSI maintains and even enhances the original performance of existing packiging.

Management Team

Nainesh Panchal

Director

Naimesh took over the reins from his father in 2008, driving our expansion into the African continent. Four years later, his brother Parth Panchal joined him. Pramukh's business has grown to over 2000 customers in 20 countries, in line with the family's vision to one day make Pramukh the world's leading high tensile wire engineering company.

Dushyant Bhatt

C.M.O - Tanzania

Dushyant holds a BBA degree in marketing, He specialized in business development, sales and marketing, and corporate strategy. Besides overseeing Pramukh's business goals, Dushyant's core responsibility is to anticipate and neutralize potential bottlenecks that can stifle company growth and identify expansion opportunities.

Satyajit Nath

C.M.O - Kenya

Satyajit was chosen as the Pamukh's CMO in 2018 to handle Kenya and its neighboring countries. Prior to joining Pramukh, Satyajit served as CMO at International Energy, Engineering and Services in Kenya.

Nalin Patel

Partner - Uganda

Nalin Patel joined the Pramukh in 2023 as a local partner, he has been working in Uganda for 20 years, he is connected to the land, so he is contributing a lot to the development of Uganda.

Gregoire Junior

BDM Cameroon

Gregoire early career began as an oil technologist with Hull-based oilseed processing company. During this tenure, he studied Chemical Engineering at the local University. He followed this up with a post, initially as a Chemical Engineer and latterly in a marketing role in South and Central Africa. Further experience was gained establishing a France office and frequent sales visits in Africa. In 2022, Pramukh invited Gregoire to join the team as BDM – Business Development. He has brought extensive contacts to the company from the over 8 countries he has visited on 3 different continents. He is committed to the development of Pramukh Steel Industries. He maintains his appetite for overseas travel developing projects, ensuring a first-class service is given in assisting clients to successfully conclude their projects, ensuring maximum efficiency and viability.