Secure your bales with the strength of PSI High-Performance Single Loop Bale Ties. Designed for speed and durability, our ties offer an easy-to-use mechanism backed by high-tensile engineering. Whether you are baling recyclables or raw materials, PSI ties are built to withstand the most demanding conditions.

The PSI Advantage: Because we control the drawing, galvanizing, and forming stages, our products consistently surpass the quality of traders like any other manufacturer or traders, who primarily supply finished goods without direct oversight of the metallurgical process.

1. Superior Materials: We use only specialized high-tensile wire, verified by NABL-accredited labs.

2. Proven Strength: Every batch is subjected to rigorous break tests at varying elongation speeds (0.25 to 5 inches per minute).

3. Manufacturing Excellence: Unlike many suppliers who act as traders, we maintain full control over our standardized inspection process to ensure our quality consistently outperforms the competition.

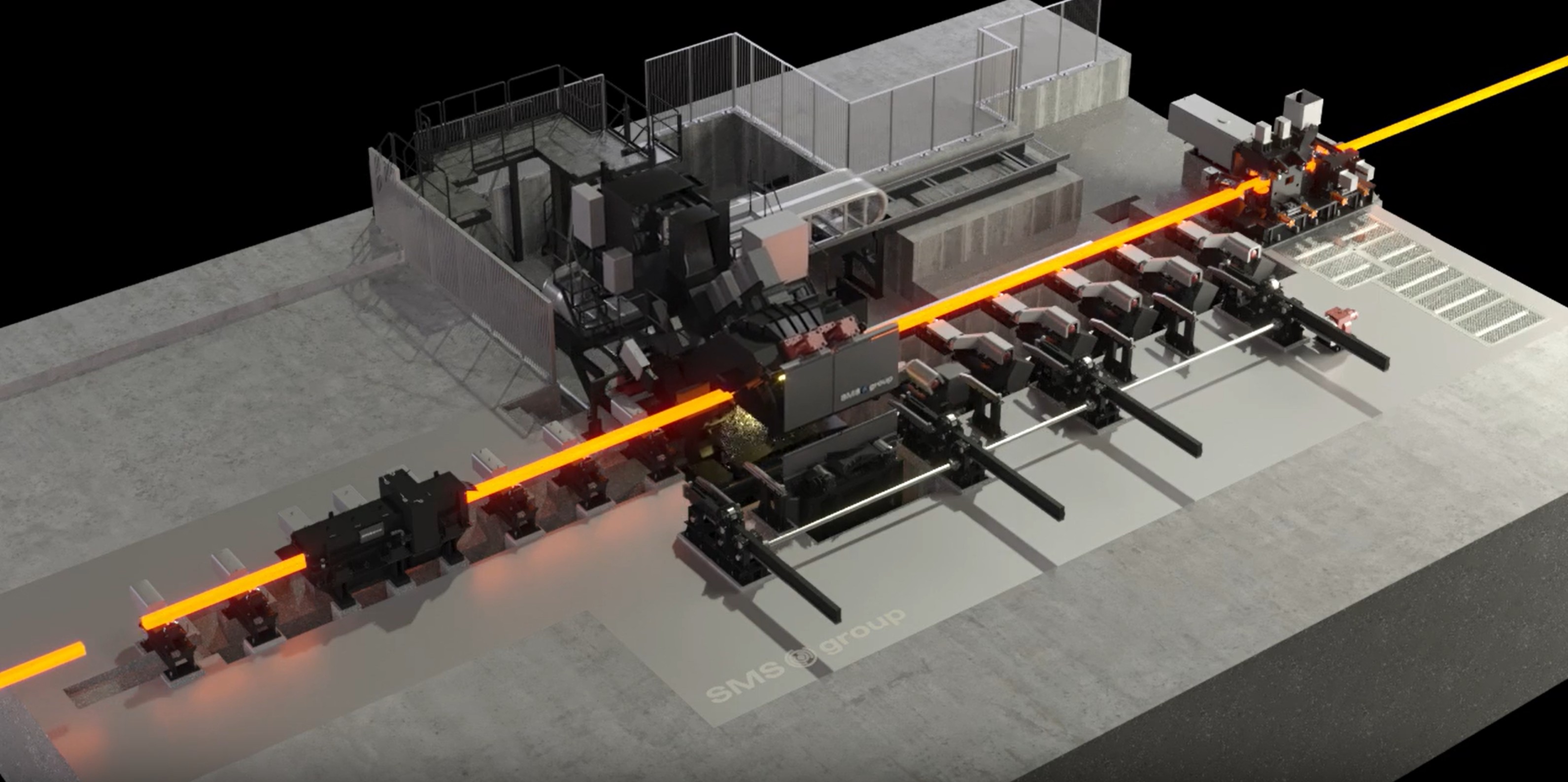

At the heart of our bale tie manufacturing is a precision wire drawing process. By pulling high-grade steel through successive dies, we create a wire that is not only thinner but significantly stronger and more flexible. This ensures that our bale ties can withstand the intense pressure of compressed materials without snapping. Unlike traders who source finished wire, we oversee the drawing process to guarantee a superior surface finish and the consistent high-tensile performance our industrial clients rely on.

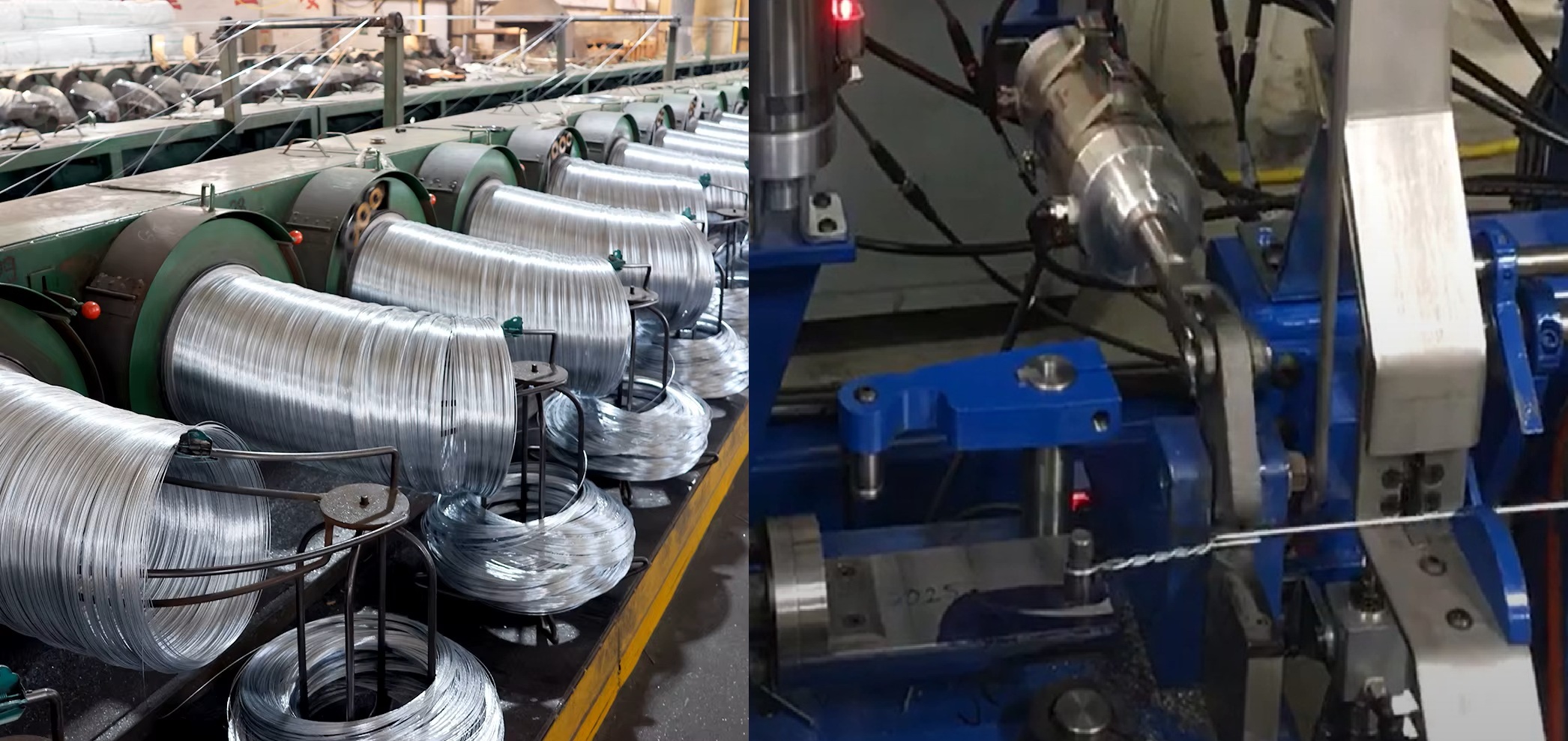

To ensure our single loop ties survive corrosive environments (such as outdoor storage or moisture-heavy recycling), the drawn wire undergoes a rigorous galvanizing process.

Acid Pickling: The wire is cleaned in a chemical bath to remove all oxides.

Thermal Coating: The clean wire is submerged in a 450°C molten zinc bath. This creates a metallurgical bond, meaning the zinc doesn't just sit on top—it becomes part of the steel surface.

Durability: This coating provides sacrificial protection; even if the tie is scratched during transport, the surrounding zinc prevents the steel core from rusting.

The CNC Straightening and Cutting Protocol To maintain the mechanical integrity of our High-Tensile single loop Bale Ties, we utilize specialized CNC machinery designed for high-carbon steel. Unlike standard cutters used by traders, our equipment is calibrated to handle the increased resistance of specialized high-tensile material without compromising the zinc coating.

Integrated Straightening: Multi-stage rollers ensure a linear deviation of less than 1mm per meter.

High-Speed Throughput: Our machines operate at speeds up to 45 m/min, allowing for high-volume production while maintaining the strict dimensional accuracy verified in our NABL-accredited labs.

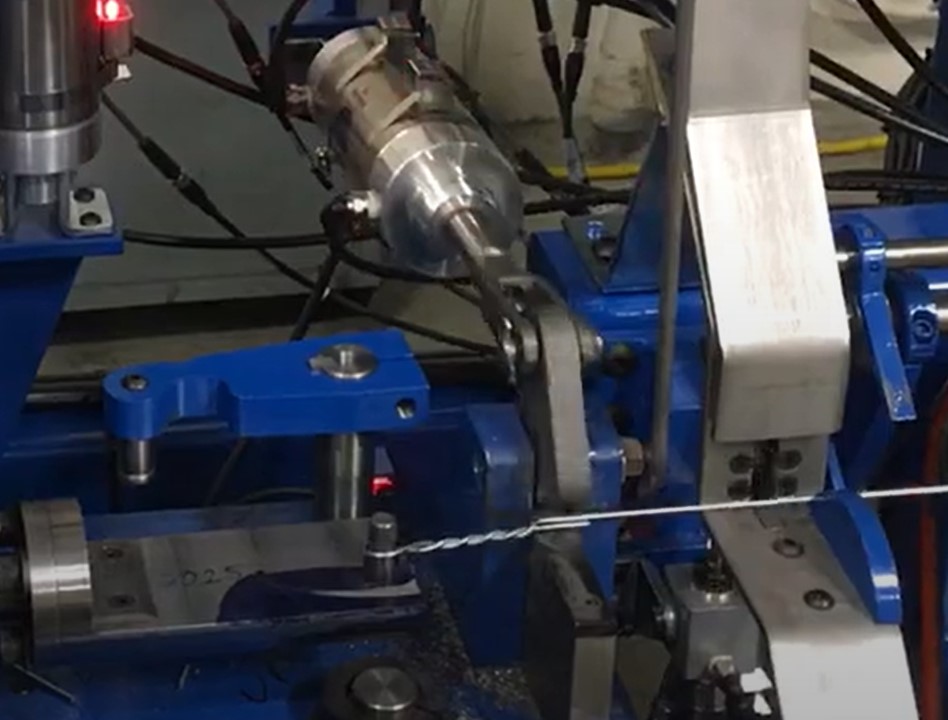

Once the high-tensile, galvanized wire is ready, it is fed into our automated forming machines. Here, the wire is cut to length and the signature "Single Loops" are twisted into each end. The precision of our machines ensures that each loop is identical, allowing for a seamless "snap-on" connection for the end-user.

The single loop wire Loop Forming Protocol Our CNC Loop Forming Machines are specifically designed for high-carbon steel wire up to 4.5mm in diameter with tensile strengths exceeding 1400 MPa.

PLC Control: Every machine is governed by a PLC panel, allowing us to adjust loop diameter and twist count to NABL-accredited standards.

Mechanical Stability: The "Closed-Loop" design is engineered to lock automatically as the baled material expands, creating a permanent closure that withstands the high tension required for cotton, tires, and foam.

High-Speed Throughput: Our production lines operate at a capacity of 35–45 pieces per minute, ensuring large-scale supply without compromising the mechanical accuracy of the individual ties.

Unlike many suppliers, our process does not end at manufacturing. We validate the mechanical integrity of every batch to ensure reliability.

Special High-Tensile Material: We verify that the raw material meets our specific grade requirements.

Standardized Break Tests: We conduct pull tests at elongation speeds of 0.25 to 5 inches per minute. This allows us to measure the exact point of failure and ensure the tie has the "memory" and ductility needed to hold a compressed bale without snapping.

Built to Perform, Packed to Protect. Your operations depend on the reliability of our ties, which is why we ensure they arrive in perfect condition. PSI offers flexible, customized packaging—from rugged wooden boxes to moisture-proof stretch wrapping—designed to withstand the rigors of global transport.

A Trusted Global Supplier From our manufacturing facilities in India to industrial hubs in the USA, Mexico, Turkey, and Africa, PSI is a leading name in the export of high-tensile Quick Links and Singl Loop Bale Ties. We don't just supply wire; we deliver peace of mind to baling operations worldwide.