We have installed top-quality, European-made machinery dedicated to the production of high-carbon and high-tensile bale wires. These high-performance lines ensure high-speed production while consistently delivering the best quality wires. Furthermore, these lines are specifically designed for the treatment of low-relaxation steel wire used in prestressed concrete and structural reinforcement. They guarantee a technological process that provides very high performance and excellent quality, a direct result of our extensive technical knowledge and long-standing experience in this specialized field.

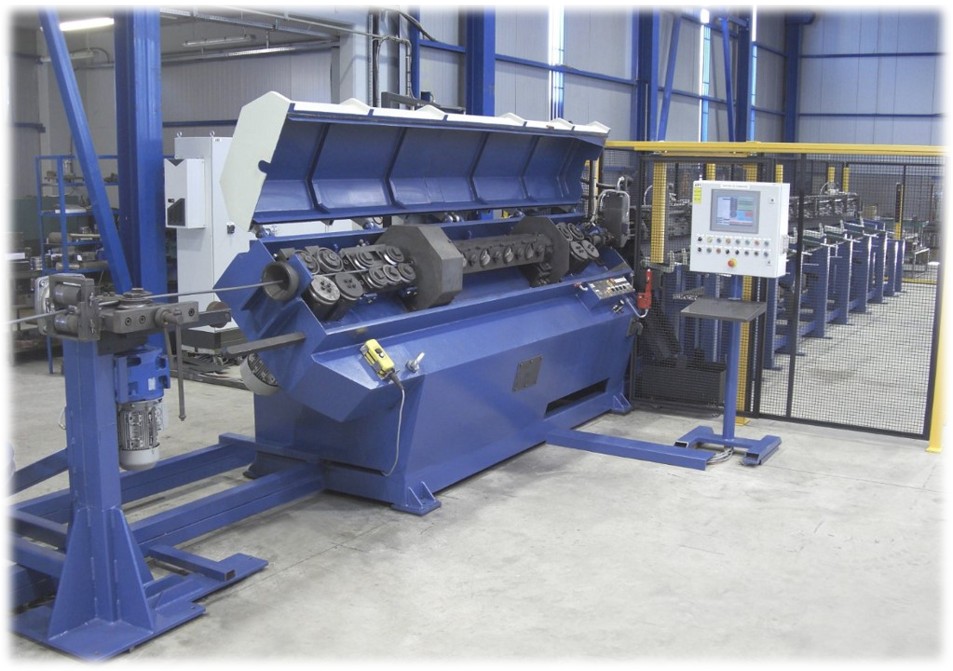

Operated with Computer Numerical Control (CNC) systems and provided with precise design instructions, a steel wire drawing machine reduces the diameter of thick steel rods into finer, more precise wires by pulling them through a series of hardened dies. These machines are essential for manufacturing products like double loop bale tei wires, single loop bale tie wires.

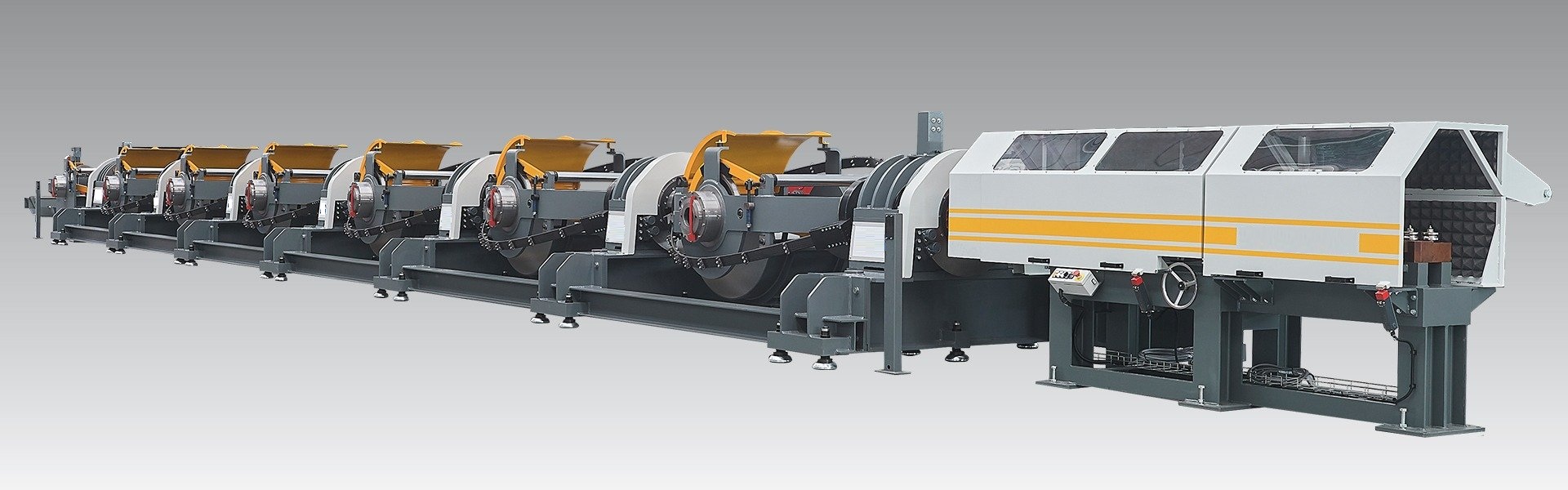

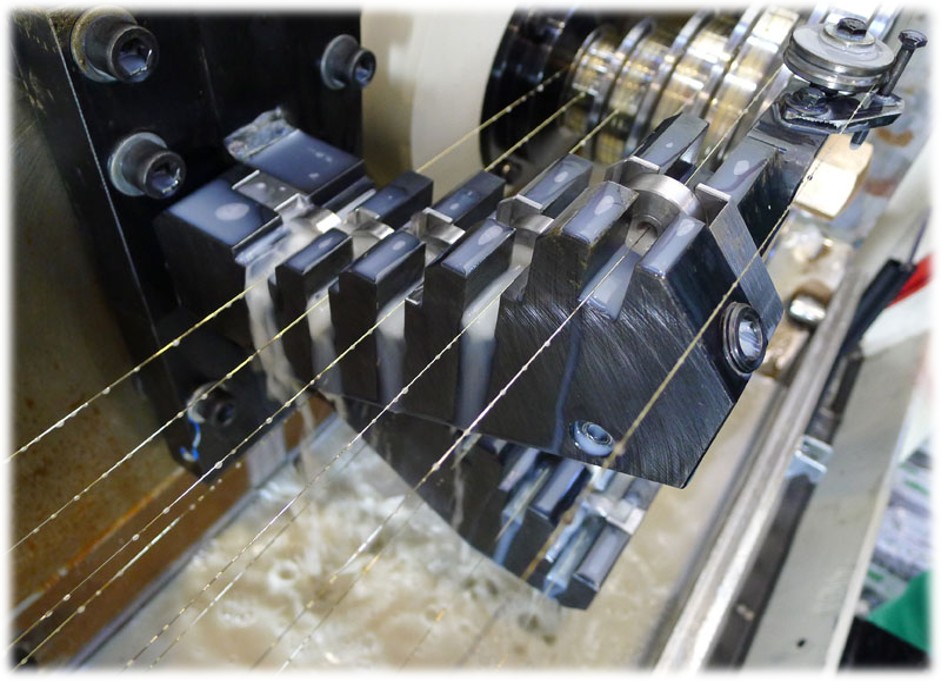

A Steel Wire Wet Drawing Machine reduces steel wire diameter by pulling it through dies submerged in a lubricating liquid (soap, oil emulsion), offering efficient cooling and lubrication for high-speed, multi-stage reductions, crucial for producing fine wires like welding or tire cord, using horizontal or vertical setups. These machines feature multiple drawing cones or drums within a water tank, with variable speeds for each stage, and are essential for creating various steel products by progressively thinning the wire.

The Vertical Drawing Machine, often referred to as a Vertical Bull Block or Inverted Vertical Wire Drawing Machine, is a type of industrial equipment used in metal processing to reduce the diameter of thick metal wire rods into thinner wires.

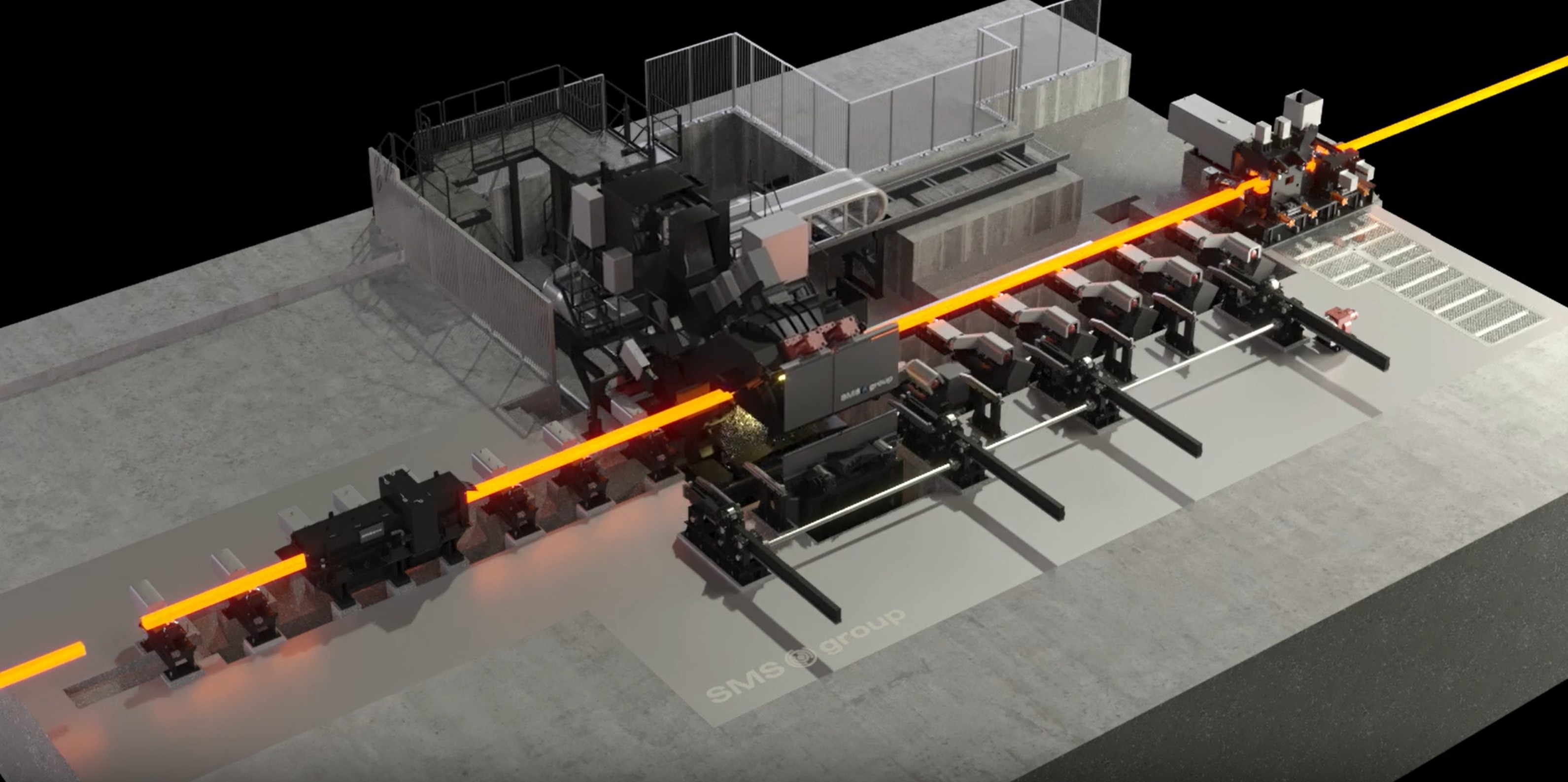

We use best quality rod breakdown machine, The main purpose of the RBD machine is to "break down" or significantly reduce the diameter of thick, incoming wire rods into an intermediate wire size, which is then ready for further processing (like intermediate or fine wire drawing).

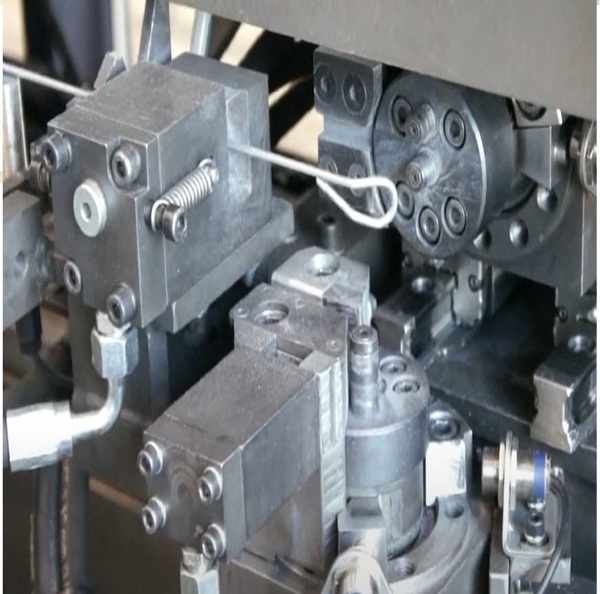

The Wire Loop Bending Machine is a highly specialized type of wire forming equipment specifically designed to create precise, consistent loops on the ends of cut-to-length wires. PSI produces high-tensile bale wires and double loop bale wires, this machine is essential to your specific manufacturing process.

the Plus Cutting Machine is the high-speed, automated system responsible for the straightening and precise length cutting of the wire before it moves on to other forming processes.