Secure your wires with the strength of PSI High Tensile Galvanized Wire. Designed for speed and durability, our wires offer an easy-to-use mechanism backed by high-tensile engineering. Whether you are baling recyclables or raw materials, PSI High Tensile wires are built to withstand the most demanding conditions.

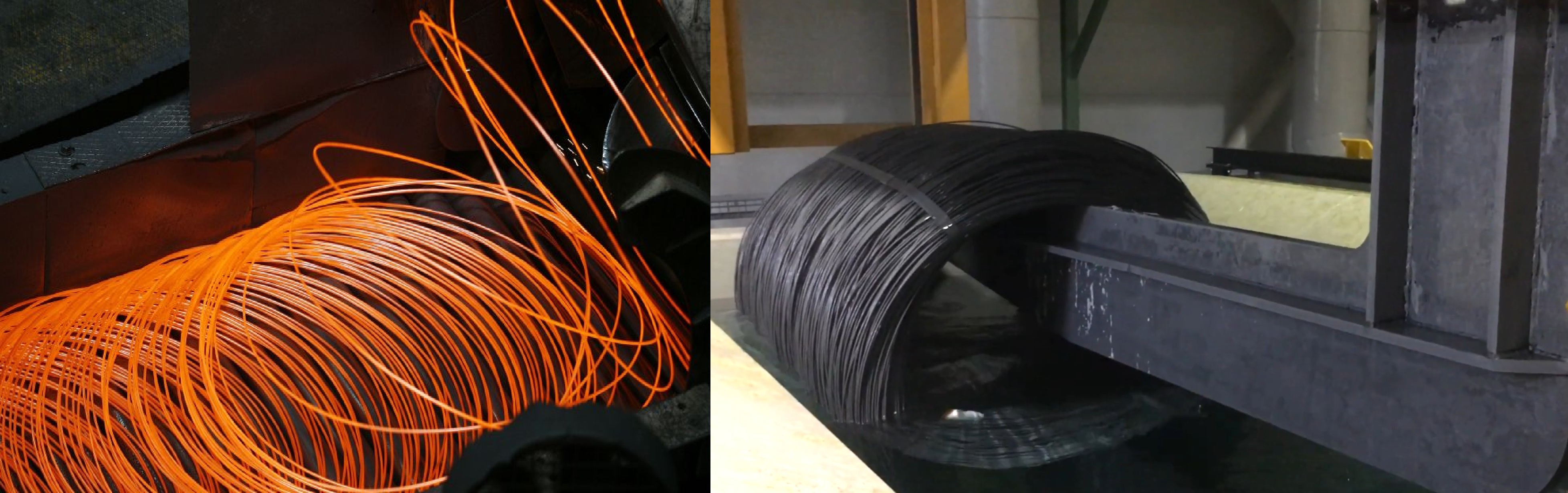

The process begins with high-carbon steel rods (typically with a carbon content of 0.45% to 0.85%). Low-carbon steel is used for standard "mild" wire, but only high-carbon steel provides the chemical foundation for the "tensile" strength and "memory" (spring-back) required for HT wire.

Mechanical Descaling: The rods are passed through rollers that bend them at sharp angles to crack the scale off.Chemical Pickling: The wire is submerged in a bath of Hydrochloric Acid (HCl) or Sulfuric Acid (H2_SO_4) to ensure a chemically pure surface.

This is the most common form of mechanical descaling. The wire rod is pulled through a series of pulleys or sheaves (usually 3 to 5) arranged in a zig-zag pattern.The Mechanism: As the rod travels over these pulleys, it is forced to bend sharply in one direction and then immediately in the opposite direction.The Result: The steel rod stretches slightly, but the brittle iron oxide scale cannot stretch. It shatters and "pops" off the surface, much like dry paint flaking off a bent piece of plastic.The Goal: Engineers aim for about $8\%$ to 8 % to 10 % deformation of the rod. This is enough to break the scale without over-hardening the steel before it even reaches the drawing dies.

Patenting is a specialized heat treatment primarily used for high-carbon steel wires (typically 0.40% to 1.0% carbon). Unlike standard annealing, which softens metal for general use, patenting is designed to create a specific microstructure—fine pearlite (sometimes called sorbite)—that allows the wire to be drawn to extremely high tensile strengths without breaking.

Austenitizing: The wire is heated in a furnace to approximately 850C – 1050C. At this temperature, the steel transforms into a uniform austenite structure.Isothermal Quenching: The wire is rapidly cooled to a temperature just above the "nose" of the TTT (Time-Temperature-Transformation) curve, typically between 450C and 550C.Transformation: The wire is held at this constant temperature until the austenite transforms into very fine pearlite. This structure consists of alternating thin layers (lamellae) of ferrite and cementite.Final Cooling: After the transformation is complete, the wire is cooled to room temperature (often in water or air) and then cleaned/coated for the next drawing stage.

To ensure our single loop ties survive corrosive environments (such as outdoor storage or moisture-heavy recycling), the drawn wire undergoes a rigorous galvanizing process.

Acid Pickling: The wire is cleaned in a chemical bath to remove all oxides.

Thermal Coating: The clean wire is submerged in a 450°C molten zinc bath. This creates a metallurgical bond, meaning the zinc doesn't just sit on top—it becomes part of the steel surface.

Durability: This coating provides sacrificial protection; even if the tie is scratched during transport, the surrounding zinc prevents the steel core from rusting.

Packing high-tensile galvanized wire is a rigorous process designed to prevent two specific types of damage: mechanical deformation (which ruins the wire's geometry for machine feeding) and "white rust" (oxidation caused by trapped moisture).

The process varies depending on whether the wire is being shipped locally or for export.

1. Primary Bundling & Strapping Before any wrap is applied, the wire must be structurally secured so it doesn't "telescope" or tangle.

Compacting: Individual coils are often pressed together using hydraulic compactors to reduce volume.

Strapping: 3 to 6 high-tensile steel straps or PET (Polyester) plastic straps are applied radially through the "eye" of the coil.

Edge Protection: For high-value HT wire, plastic or heavy-duty cardboard "V" protectors are placed under the straps to prevent them from biting into and kinking the outer layer of wire.

2. Moisture & Corrosion Protection Since galvanized wire is sensitive to condensation (which forms "white bloom"), the wrapping layers are critical.

Layer 1 (Inner): VCI (Vapor Corrosion Inhibitor) Film or Paper. This chemically active layer releases a dry vapor that prevents oxidation on the zinc surface.

Layer 2 (Middle): LDPE/Stretch Film. A waterproof plastic layer that seals the coil from external humidity and rain.

Layer 3 (Outer): HDPE Woven Fabric or Hessian. This is a tough, tear-resistant layer (often blue, white, or yellow) that protects the inner layers from being punctured by forklift tines or hooks during transit

Integrated Straightening: Multi-stage rollers ensure a linear deviation of less than 1mm per meter.

High-Speed Throughput: Our machines operate at speeds up to 45 m/min, allowing for high-volume production while maintaining the strict dimensional accuracy verified in our NABL-accredited labs.

Unlike many suppliers, our process does not end at manufacturing. We validate the mechanical integrity of every batch to ensure reliability.

Special High-Tensile Material: We verify that the raw material meets our specific grade requirements.

Standardized Break Tests: We conduct pull tests at elongation speeds of 0.25 to 5 inches per minute. This allows us to measure the exact point of failure and ensure the tie has the "memory" and ductility needed to hold a compressed bale without snapping.

Built to Perform, Packed to Protect. Your operations depend on the reliability of our wires, which is why we ensure they arrive in perfect condition. PSI offers flexible, customized packaging—from rugged wooden boxes to moisture-proof stretch wrapping—designed to withstand the rigors of global transport.

A Trusted Global Supplier From our manufacturing facilities in India to industrial hubs in the USA, Mexico, Turkey, and Africa, PSI is a leading name in the export of high-tensile galvanized wires. We don't just supply wire; we deliver peace of mind to baling operations worldwide.